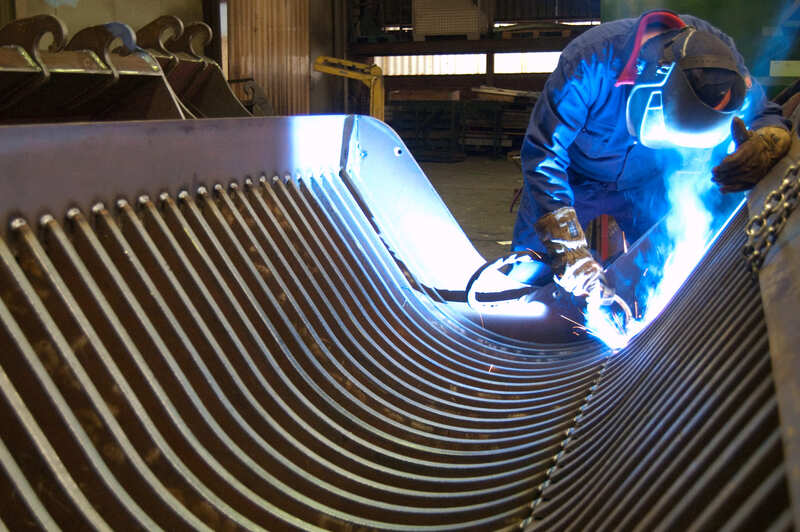

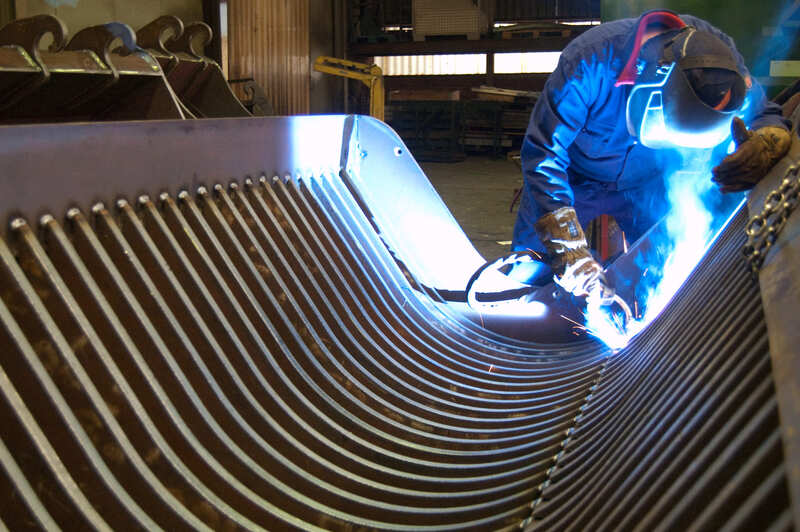

You’ll first need to complete a safety officer course to achieve the position of safety officer in the welding industry. Acquiring the proper training with a safety officer course will equip you with all you need to know about different welding industry hazards and how to prevent them successfully. But unfortunately, the welding profession can be full of dangers, and countless people suffer injuries each year due to improper safety procedures in the workplace. This article takes a closer look at some of the risks of the welding industry and the critical role a comprehensive safety officer course presented by a trusted organisation like EMCARE can play in protecting you and your welding staff.

Safety Officer Course: Why Is It Necessary To Have A Safety Officer In The Welding Industry?

The welding industry is full of a variety of dangers, and this is usually caused by the dangerous equipment used. The high heat and excessive light emitted from a welder’s equipment can easily harm an individual. Even expertly trained welders can easily injure themselves, so it is necessary to have a safety officer who constantly oversees staff members’ safety. The safety officer ensures that all safety protocols are continuously followed effectively. We at EMCARE make this easy through our safety officer course in which these skills are taught. A safety officer course can prevent many workplace accidents, keeping your health and safety standards high.

Safety Officer Course: Possible Hazards In The Welding Industry

In South Africa, welding and welding practices are in demand. This, in turn, means that there is also a higher demand for safety officers and safety officer courses. Suppose you plan on entering this industry as a safety officer. In that case, you must complete your safety officer course through a trusted provider with the correct credentials. We at EMCARE are fully certified to train the next batch of great safety officers. Unfortunately, with the increase in demand for welding, many businesses do not follow the proper safety procedures, which can lead to workplace risks. The following are some of the most common safety hazards in the welding industry. With an EMCARE safety officer course, you will learn how to identify and mitigate these hazards effectively.

- The physical dangers in the welding industry

The physical dangers of the welding process are usually caused by the equipment and tools needed to complete the job, which can be hazardous. Welders are often in danger of heavy equipment falling on them. In extreme cases, these heavy objects commonly cause crushed toes, fingers, or even broken bones. During the cutting process in welding, workers are exposed to sharp pieces of metal, which could easily harm someone who does not handle these pieces with care. Exposure to high heat can cause burns, and the intense light produced when welding can cause severe eye damage.

Luckily most of these physical hazards can easily be prevented if you know what to look for. A safety officer course can ensure you know how to protect yourself and your workers from these potential injuries. Then, with the proper protective gear and the correct safety measures, your welding business can have little to worry about.

- Dangerous gases and fumes

During the welding process, different types of gases and fumes are emitted. For example, welding can produce nitrogen, carbon monoxide, hydrogen fluoride, arsenic and other harmful gases. Overexposure to these gases can be detrimental and leave you with long-term health implications. In welding, employees risk suffering damage to their respiratory and nervous systems and are at a higher risk of cancer and kidney damage. Following the safety measures set out in an EMCARE safety officer can protect welders from experiencing these health-related issues.

- Electrocution

An electric shock is dangerous for any welder and could cause serious injury. There is a live current used to melt metal during the welding process, and if the welder touches two metal pieces with a high current, this shock can be transferred to the body, causing injury. The shock can cause injuries, but residual damage can also occur due to extenuating factors like falling from a high place after an electric shock leaves the welder immobile. A safety officer course can teach safety officers how to train welders to avoid electric shocks on the job.

- Fire Hazards

Fire risk is quite common in the welding industry due to the sparks made during the welding process. These sparks can travel a far distance and quickly cause a fire if there is flammable material nearby. Electric welding can also cause severe burns on your skin and damage from ultraviolet radiation. Having a safety officer ready to deal with these situations is essential.

Safety Officer Course: Roles And Responsibilities Of A Safety Officer In The Welding Industry

With the training you will receive in an EMCARE safety officer course, you will be fully equipped to identify and manage the hazards in welding industries. In addition, a safety officer should also implement safety regulations and procedures that make the workplace safer. The following are some of the steps taken by safety officers to improve safety in the workplace:

- Ensuring staff are adequately trained: Welders must be prepared to do the job correctly while following adequate safety measures.

- Ensuring proper welding safety gear is utilised: Welding safety gear must always be used, and a safety officer can ensure appropriate training on effectively using this gear. Safety gear is one of the most effective ways to prevent welding injuries.

- A safety officer can keep track of all equipment: If equipment is faulty, it can cause fires and hazards, and ensuring it is in working order will help keep staff members safe.

- Conduct a risk assessment: This takes note of all possible risks in the business to put safety measures in place.

The welding industry has many dangers, and an on-site safety officer is crucial. The EMCARE safety officer course will equip you with all the skills and necessary qualifications to start a career as a safety officer. In addition, completing the safety officer course will teach you the importance of occupational health and safety in the welding industry and how to ensure the safety of all workers. So if you are ready to work in the welding industry today, don’t hesitate to visit the EMCARE website and see when you can complete your safety officer course.